MAXI - HDD

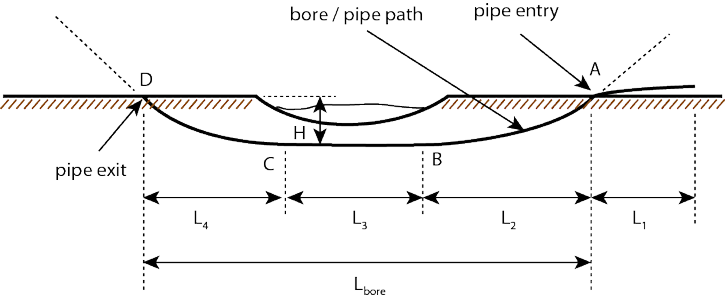

ASTM International F1962, Standard Guide for Use of Maxi-Horizontal Directional Drilling for Placement of Polyethylene Pipe or Conduit Under Obstacles, Including River Crossings, provides recommended procedures for the placement of PE pipe using maxi-HDD. The ASTM International document provides overall guidelines, addressing preliminary site investigation, safety and environmental considerations, regulations and damage prevention, bore path layout and design, implementation, and inspection and site cleanup. One of the significant contributions of ASTM International F1962 is the provision of a rational, analytical method for selecting the polyethylene pipe strength based upon the estimated installation and post-installation (operational) loads on the polyethylene pipe. Thus, ASTM International F 1962 provides a means of determining project feasibility, as well as initial design information.

While ASTM International F1962 may be purchased from the ASTM International website (www.ASTM.org), the overall guidelines, including preliminary investigation and implementation procedures, as well as the detailed design methodology for selection of the proper pipe strength, are reflected in Chapter 12 of the Plastic Pipe Institute (PPI) Handbook of Polyethylene Pipe

In addition, the ASTM International F1962 methodology is now available in a free online tool designated as PPI BoreAid™