Design Guidelines

The engineering design procedure required for a slip lining project consists of the five steps described below.

- Select a pipe liner diameter. To attain the maximum flow capacity, the largest feasible diameter should be selected for the pipe liner. This is limited by the size and condition of the original pipe through which it will be inserted. The selection of a polyethylene liner that has an outside diameter 10% less than the inside diameter of the pipe to be rehabilitated will often be appropriate, although lower clearances may be possible in larger diameter pipes (e.g., greater than 24-inch), assuming that the conditions of the existing pipe structure permit insertion of the liner.

- Determine a liner wall thickness. The strength of the pipe and ability to withstand anticipated installation and in-service loads is determined by its wall thickness, typically specified by the DR value (outer diameter divided by wall thickness). The primary installation load corresponds to the pulling force applied at the leading end of the pipe sufficient to compensate for the frictional drag force along the bottom of the HDPE pipe as it is pulled into the original pipe. The wall thickness must be selected to provide a tensile strength compatible with the estimated pull force, including an appropriate safety factor. (A similar technique may be used to estimate the minimum wall thickness for a pushing operation.

- The primary in-service loads for the replacement HDPE pipe will depend on the application -- i.e., non-pressure (e.g., gravity sewer) or pressure (e.g., gas or water). For non-pressure applications, the pipe stiffness (or wall thickness) must be sufficient to withstand the external hydrostatic pressure due to the anticipated height of the water table above the pipe. For pressure applications, the replacement pipe must withstand a combination of internal and external forces.

Additional details are provided in Chapter 11 of the Plastic Pipe Institute (PPI) Handbook of Polyethylene Pipe.

- Determine the flow capacity. The insertion of a smaller pipe within the existing system may appear to reduce the original flow capacity. However, in the majority of slip lining applications, this is not the case. The polyethylene liner is extremely smooth in comparison to most piping materials, resulting in improved flow characteristics. A comparison of the original and new flow rates may be obtained based on use of two widely used equations: the Manning Equation and the Hazen-Williams Approximation for other than gravity flow systems. Additional details are provided in Chapter 11 of the Plastic Pipe Institute (PPI) Handbook of Polyethylene Pipe.

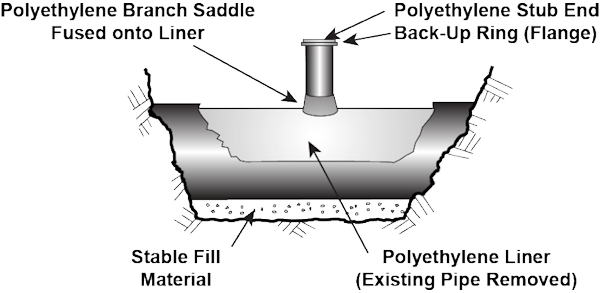

- Design necessary accesses. The polyethylene liner will need to be connected to existing system components or appurtenances. Proper planning for a rehabilitation project must include the specific engineering designs by which these connections will be made. Gravity flow pipeline rehabilitation often requires that the individual liner lengths be terminated at manholes or concrete headwalls that already exist within the system that is being slip lined. The annular space at these locations must provide a water-tight seal against continued infiltration in the void area that exists between the liner and the original pipe where they connect to these structures.

Additional details are provided in Chapter 11 of the Plastic Pipe Institute (PPI) Handbook of Polyethylene Pipe

- Develop the contract documents. When the rehabilitation design has been completed, attention should be focused on writing the specifications and contract documents that will ensure a successful installation. Reference documents for this purpose include: ASTM International D3350, ASTM International F585, ASTM International F714, and ASTM International F894. To assist further in the development of these documents, a model slip lining specification is available from the Plastics Pipe Institute, Chapter 11 Guidance and Recommendations on the Use of Polyethylene (PE) Pipe for the Sliplining of Sewers.