Pipe Connection to the Manhole

The relatively high thermal elasticity of the PE material causes significant changes in the pipe length; one inch change in length per 100 ft of pipe for each 10ºF temperature change. Therefore, in extreme hot or cold weather when there is significant difference between the temperature of the deep soil and the ambient air temperature, it is recommended to allow the pipe to rest for 12 to 24 hours prior to installing tie-ins. Similarly, when pipe has been pulled to a significant portion of its allowable tensile load, it may be prudent to let the pipe rest before connecting to other pipes, fittings, manholes, and laterals. This procedure allows the pipe to rebound from any stretch that may have occurred during bursting.

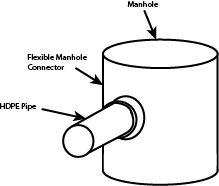

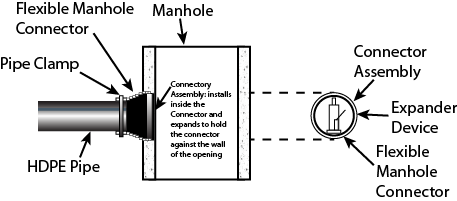

In most pipe bursting applications, the sewer line is old and deteriorated, as well as the manholes along the line. In most cases, it is economical, on a life-cycle basis, to replace the old deteriorated manholes and use their location as pulling or insertion shafts. When existing manholes are replaced with new ones, connections to PE pipe can be made using flexible rubber manhole connectors, or "boots." A pipe clamp is used to tighten the boot around the PE pipe as shown below.

Connecting PE Pipe to New Concrete Manhole