Slip Lining

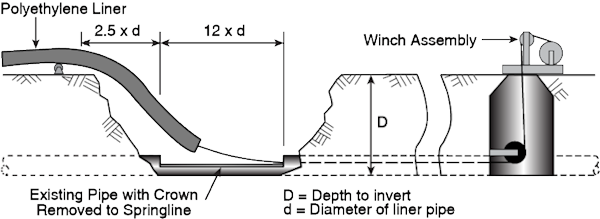

The slip lining method involves accessing the deteriorated line at strategic points within the system and subsequently inserting polyethylene pipe lengths, joined into a continuous tube, throughout the existing pipe structure.

This technique has been used to rehabilitate gravity sewers, sanitary force mains, water mains, outfall lines, gas mains, highway and drainage culverts, and other piping structures with extremely satisfactory results. It is equally appropriate for rehabilitating a drain culvert 40 feet long under a road or straight sewer line with manhole access as far as 1/2 mile apart. The technique has been used to restore pipe as small as 1-inch, and there are no apparent maximum pipe diameters. The basic procedure involves pulling (or pushing) the replacement HDPE pipe into the original pipe.

The limitations on allowable depth and segment length for the replacement pipe are determined by the physical characteristics (stiffness and strength) of the HDPE product employed. Conversely, the selection of an appropriate pipe wall thickness is part of the design process to ensure a reliable installation, based on the project requirements.