Pneumatic Pipe Bursting Systems

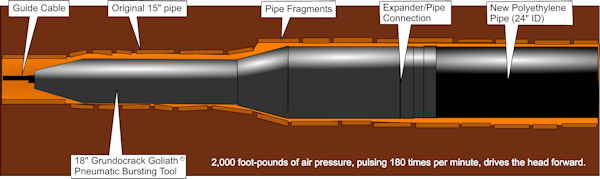

The most common pipe bursting method is the pneumatic system. In the pneumatic system, the bursting tool is a soil displacement hammer driven by compressed air and operated at a rate of 180 to 580 blows per minute. It is similar to a pile-driving operation but in a horizontal direction. The percussive action of the hammering cone-shaped head is also similar to hammering a nail into the wall; each hammer pushes the nail a short distance as shown in the figure below. With each stroke, the bursting tool cracks and breaks the old pipe and the expander on the head, combined with the percussive action of the bursting tool, pushes the fragments and the surrounding soil radially outward, providing space to pull in the new PE pipe. The expander can be front-end (attached to the front of the hammer) for pipes smaller than 12" or back-end (attached to the rear of the hammer) for pipes larger than 12". The front-end expander allows withdrawing the hammer through the PE pipe after removing the expander from the existing manhole at the pulling shaft without damaging the manhole. The tension applied to the guide cable keeps the bursting head aligned with the old pipe, pressed against the existing pipe wall, and pulls the new PE pipe behind the head. An air pressure supply hose is inserted through the PE pipe and connected to the bursting tool. The bursting starts once (1) the head is attached to the new pipe, (2) the winch cable is inserted through the old pipe and attached to the head, (3) the air compressor and the winch are set at constant pressure and tension values. The process continues with little operator intervention until the head reaches the pulling shaft at which point it is separated from the PE Pipe.