PIPE EMBEDMENT MATERIALS

The embedment material may be imported, such as a crushed stone, or it may be the ("native") material excavated from the trench to make room for the pipe. The embedment material should provide adequate strength, stiffness, uniformity of contact (i.e., completely envelop the pipe) and stability to minimize deformation of the pipe due to earth pressures. In general, soils with large grains such as gravel have the highest stiffness and thus provide the most supporting strength. Aside from the grain characteristics, the density has the greatest effect on the embedment's stiffness. Loose soil will permit more deflection of pipe for a given load than dense soil.

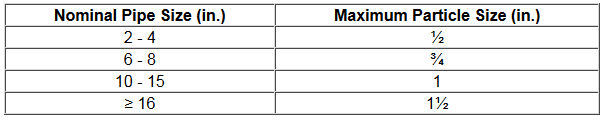

ASTM International D 2321 describes five related embedment classes. Class I and II soils are granular and tend to provide the maximum embedment support as illustrated by the potentially high E' (modulus of soil reaction) values. Class I material is generally manufactured aggregate, such as crushed stone, while Class II materials consist of clean sands and gravels and are more likely to be naturally occurring soils such as river deposits. The favorable characteristics of these type soils, or in combination, lead many designers to select these materials when they are readily and economically available. Maximum aggregate size of Class I and Class II materials when used next to the pipe (i.e., bedding, haunches and initial backfill) should be compatible with the pipe size. The smaller the rock size, the easier it is to place in the haunches.

When the pipe is located beneath the ground water level, consideration must be given to the possibility of loss of side support through soil migration (ground water conveyance of fine soil particles into voids of coarser soils), which may occur with fine sand, silts and special ("dispersive") clays. This situation is exacerbated where a significant gradient exists in the ground water from outside of the trench toward the inside of the trench. Refer to PPI PE Handbook, Chapter 7 (Under Migration) for detailed discussion.

Class lIl and Class IVA materials provide less supporting stiffness than Class I or II materials for a given density or compaction level, in part because of the increased clay content. In addition, they require greater compaction effort to attain specified densities and their moisture content must be closely controlled within the optimum limit, especially for Class IVA soil, which is typically limited to applications with pressure pipe at shallow cover.

Class IVB and Class V materials offer only minimal support for a buried pipe and are often difficult to properly place and compact. Where the embedment material becomes saturated, provide sufficient depth to avoid flotation; refer to PPI PE Handbook, Chapter 7.